TRB is a Groupe CB company - Find More

STEEL

TRB expertise at the service of your steel production facilities

Tailor-made engineering solutions to optimize steel production

At the heart of steelworks, each melting, refining or casting operation imposes extreme thermal and mechanical stresses. Steel ladles, cast-iron ladles and tundishes are subjected to continuous stresses that put their durability to the test. Maintaining the reliability of this equipment remains essential to ensure production continuity and guarantee steel quality.

Thanks to the experience of our teams and the expertise of our design officewe develop tailor-made engineering solutions. From initial design to on-site support, our engineers and technicians apply their know-how and digital tools to guarantee solutions perfectly aligned with your specific needs.

We round out our offering with state-of-the-art services: thermal simulation studies, in-service inspections using thermal imaging cameras, and rigorous selection of the most suitable materials.

This integrated approach combines innovation and reliability to guarantee the long-term performance of your production tools.

Our

solutions can be implemented :

In cast-iron ladles

In steel ladle

With top ladle crown pieces and holding and heating lids in concrete or ECOFIB, specific safety concretes for steel ladles, impact slabs and seat bricks in precast concrete, pouring spouts (dedicated to steel and slag) precast in our ECOFIB range, filler concrete between bricks and for the bottom of the ladle to protect against wear. We can monitor the external temperature of the ladle with our infrared cameras, and our sensors for thermal simulation.

In tundish

With safety concrete, as well as prefabricated covers, ECOFIB heating covers, dams, impact slabs and other prefabricated solutions.

Electric furnaces (EAF)

They are made up of parts weighing from a few kilos (top of furnace, lintel) to several tons (vaults weighing from 4 to 12 t). Our vaults are made of poured/vibrated concrete and meet the various constraints of vaults (abrasion, corrosion, thermal shocks, mechanical resistance).

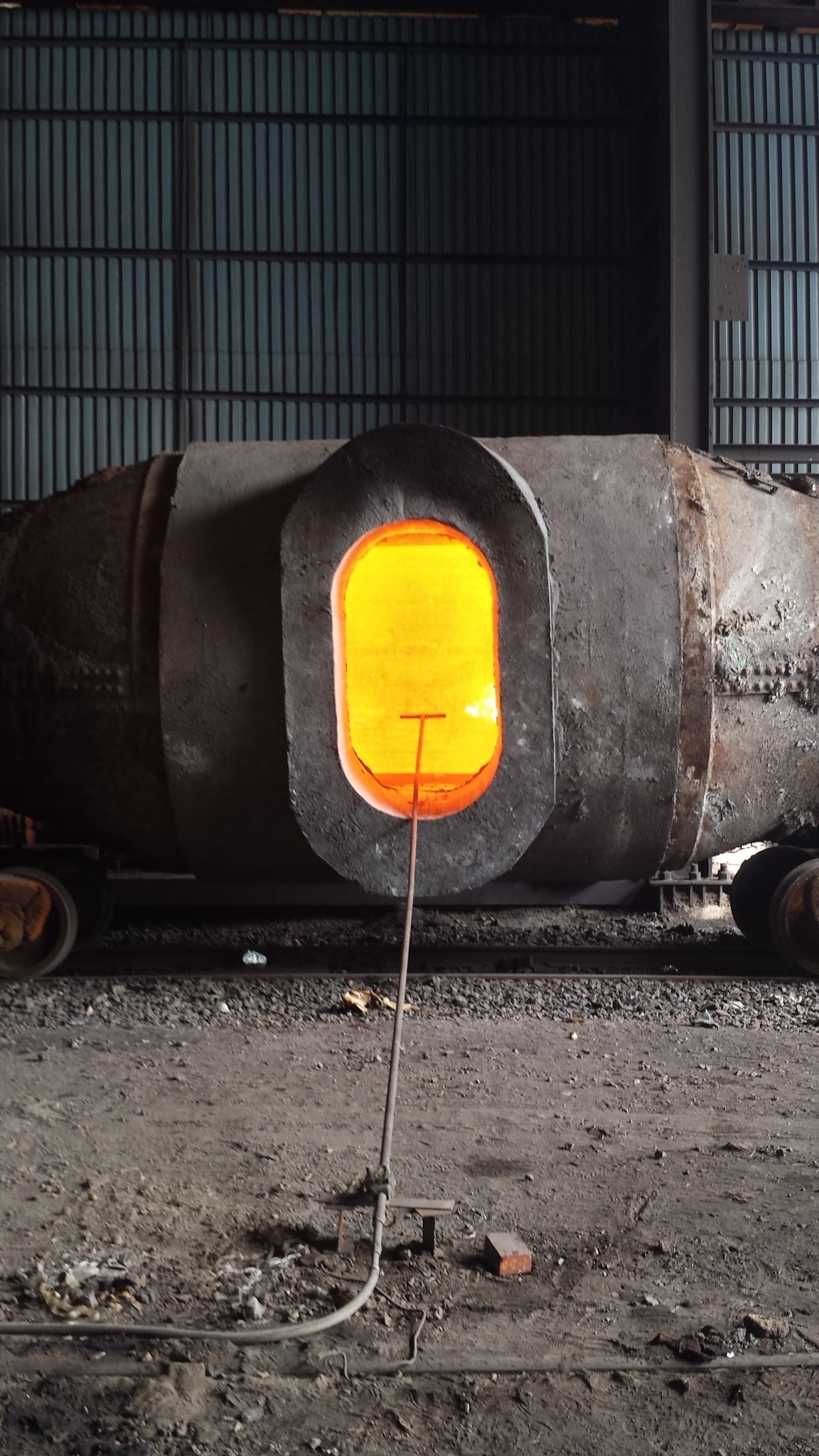

In "Torpedo" cars

With ECOFIB spout and cover parts for maintenance or desulfurization, wear concrete for spout and under-spout, and gunning products for internal walls.

Our

service

TRB also provides industrial smoke ventilation services. Our added value? We provide a complete range of services on your industrial sites, from design to implementation, to guarantee you high-performance products and technical solutions.