TRB is a Groupe CB company - Find More

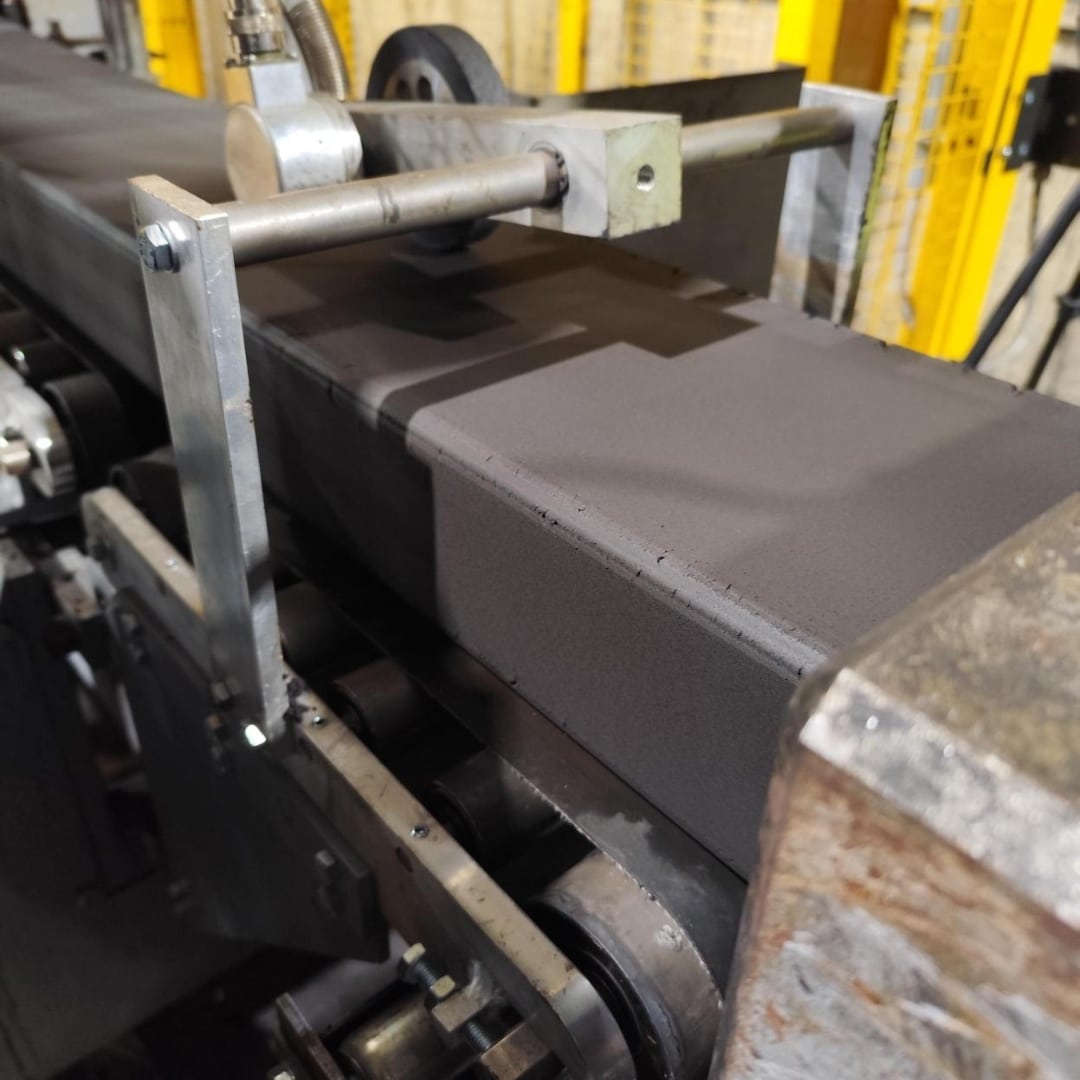

blast furnaces

High-performance refractory lining for blast furnaces

Extend the life of your equipment with proven refractory solutions

For steelmakers and blast furnace operators, ensuring safety, durability and control of operating costs remains a constant challenge. Extreme thermal stress, accelerated wear and tear, and the need to reduce unscheduled shutdowns call for reliable, high-performance refractory solutions.

European leader in refractory concretes for blast furnace runners, TRB draws on its solid R&D capabilities and the expertise of its engineers to design innovative products. Our refractory division offers a complete range of concretes, as well as gunning and shotcrete repair solutions, specially designed to optimize plant life and efficiency.

Marketleader in Taphole Clay.

TRB is recognized as a key player in blast furnace taphole maintenance.

We offer solutions to suit every situation. During the operating phase, we inject our Taphole Clay ECOTAP, specially formulated to obstruct gas passages and limit liquid infiltration into blind holes. During scheduled shutdowns, we apply ECOGROUT, our high-performance injection product, guaranteeing reliable, long-lasting return to service.

Thanks to this expertise, TRB secures your operations and extends the life of your blast furnaces.

Protect your system with ECOFIB solutions

We are also developing ECOFIB solutions to protect installations and personnel working in the vicinity of thermally exposed areas, such as those on blast furnace floors. for example, to protect plugging and unplugging machines, gutter covers or the tapping area.ECOFIB 's thermomechanical properties make all the difference.

Our ECOFIB solutions are designed to enhance the safety of :

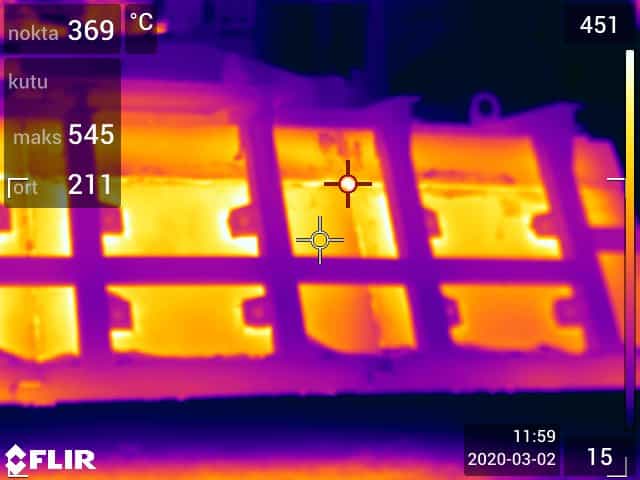

Monitoring solutions for

better management

We also offer innovative monitoring solutions, such as our instrumented gullies, developed by our engineers, and combined with the use of 3D scanners and thermal cameras.

These tools can be usedto help decision-making for the management and shutdown of the main runner campaigns.

Our

service

TRB also provides industrial smoke ventilation services. Our added value? We provide a complete range of services on your industrial sites, from design to implementation, to guarantee you high-performance products and technical solutions.