TRB is a Groupe CB company - Find More

Foundry

Foundry products tailored to your needs

Our solutions

foundry

If TRB has been able to offer its customers a wide range of foundry products for over 25 years, it's because we have a design office capable of devising solutions to suit every situation, and innovating to meet expectations.

Proven in other fields of application (steelworks, blast furnaces, etc.), these foundry-specific products are the result of research and testing carried out by our engineers and technicians. Our engineers and technicians are at your side, upstream and downstream, from design to on-site implementation, with one objective in mind: to offer you products that enhance the performance of your production tools.

We offer you refractory solutions for lining melting tools, including thermal calculations, lining studies, assembly, drying, metallization and technical support.

Our solutions:

Transfer and pouring pockets:

Transfer and casting ladles in precast shapes or in cast concrete solution, on site or in our workshops, and processing ladles in molds or wire-drilled.

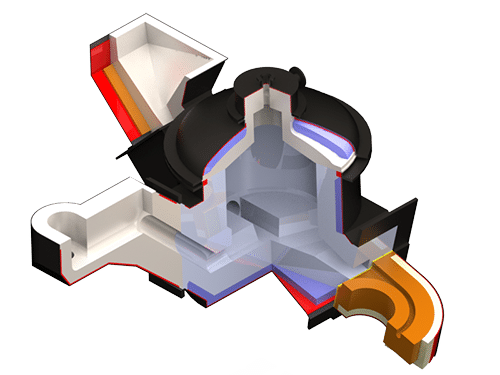

Channel kiln :

Channel induction furnaces : our services include thermal studies, assembly, drying, metal casting and technical support. For furnaces under 6 t, we can refurbish the vessel and siphons in our workshops (no on-site drying). We carry out the complete lining of the inductor, including parameter monitoring (Cos phi). TRB also offers a thermographic study to establish the homogeneity of refractory masses.

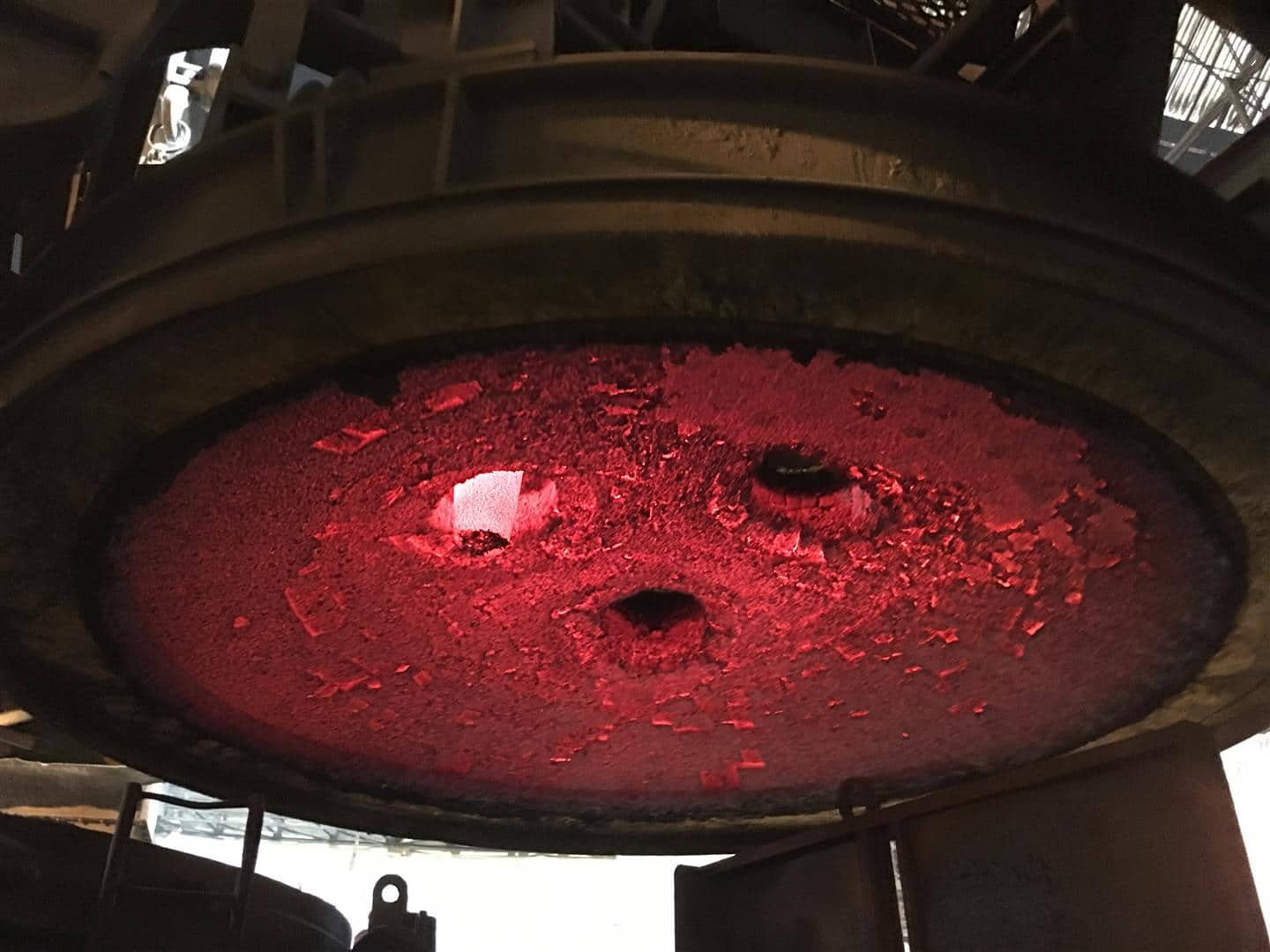

ECOFIB cupola solution

Innovative solutions for cupola furnaces, miniature blast furnaces, cold-wind or hot-wind furnaces.

Shaped parts (pickling tongs and planes, heating lids and lids, spouts, etc.) all in ECOFIB Full Internal Lining with our refractory castables.

Arc furnaces

Arc furnaces (EAF) with cast/vibrated concrete vaults to meet the various constraints of the vaults (abrasion, corrosion, thermal shocks, mechanical resistance) and combustion chambers to recover gases and dust, in concrete, anti-abrasion materials or Ecofib.

As part of its "customer service" approach, TRB is also committed to the implementation of its products for both major repairs and day-to-day maintenance.

Our

services

TRB also provides industrial smoke ventilation services. Our added value? We provide a complete range of services on your industrial sites, from design to implementation, to guarantee you high-performance products and technical solutions.