TRB is a Groupe CB company - Find More

Precast Shapes

ECOKAST & ECOFLOW: Excellence in Precast Refractory Components

High-performance precast solutions for extreme thermal conditions

The 50 years' experience in the design and manufacture of precast shapes has given us undeniable know-how and technical expertise. As a result, we can offer you tailor-made solutions to meet your exact requirements.

Precast shapes give you perfect control over casting parameters. They are an excellent technical alternative to the constant reduction in the duration of your maintenance work. Already dry and ready to use, these precast shapes reduce repair time and enable faster tool availability. The result is improved performance and productivity!

Formulated by us and Made with refractory castables (ECOKAST and ECOFLOW), or from products using our ECOFIB solution (refractory composite with high fiber content), these parts (which can weigh up to 12 t) meet the requirements of applications requiring high resistance to thermal and mechanical shock.

Meeting tomorrow's challenges

A forerunner in innovation in the refractory market, TRB is already anticipating economic and social trends, environmental issues and the limitation of resources and raw materials, by constantly developing innovative solutions.

For example, by incorporating up to 15% recycled materials in the design and manufacture of new products.

ecofib

Our ECOFIB solution

Precast solutions reinforced with metal fibers

Designed for high-temperature industries, our solutions address the most critical issues. Premature wear of steel parts, severe thermal and mechanical stress, rising maintenance costs and operator safety risks are just some of the challenges we meet with ECOFIB.

ECOFIB precast shapes , with their very high metal fiber content, are formulated to withstand extreme environments. Produced at our Nesles plant, they combine different types of fiber and refractory slip for customized designs, with an annual production capacity of over 400 tons.

Thanks to their exceptional resistance to thermal and mechanical shock and abrasion, ECOFIB solutions extend plant life, reduce unscheduled downtime and improve the availability of production tools.

Backed by the expertise of our design office and rigorous technical support, our precast shapes are ready to use. They reduce intervention times, guarantee stable performance and provide manufacturers with a durable, reliable and easy-to-maintain solution.

pureblox 1400

Innovation PUREBLOX 1400

Health, performance and sustainability in a single solution

High-temperature industries, and in particular steel furnace operators, have to deal with a double constraint.

On the one hand, to ensure high-performance thermal insulation to maintain the productivity and safety of their facilities.

On the other, the health risks associated with the use of ceramic fibers classified as CMR (carcinogenic, mutagenic and toxic to reproduction). This dilemma calls for a concrete response that combines industrial efficiency and operator protection.

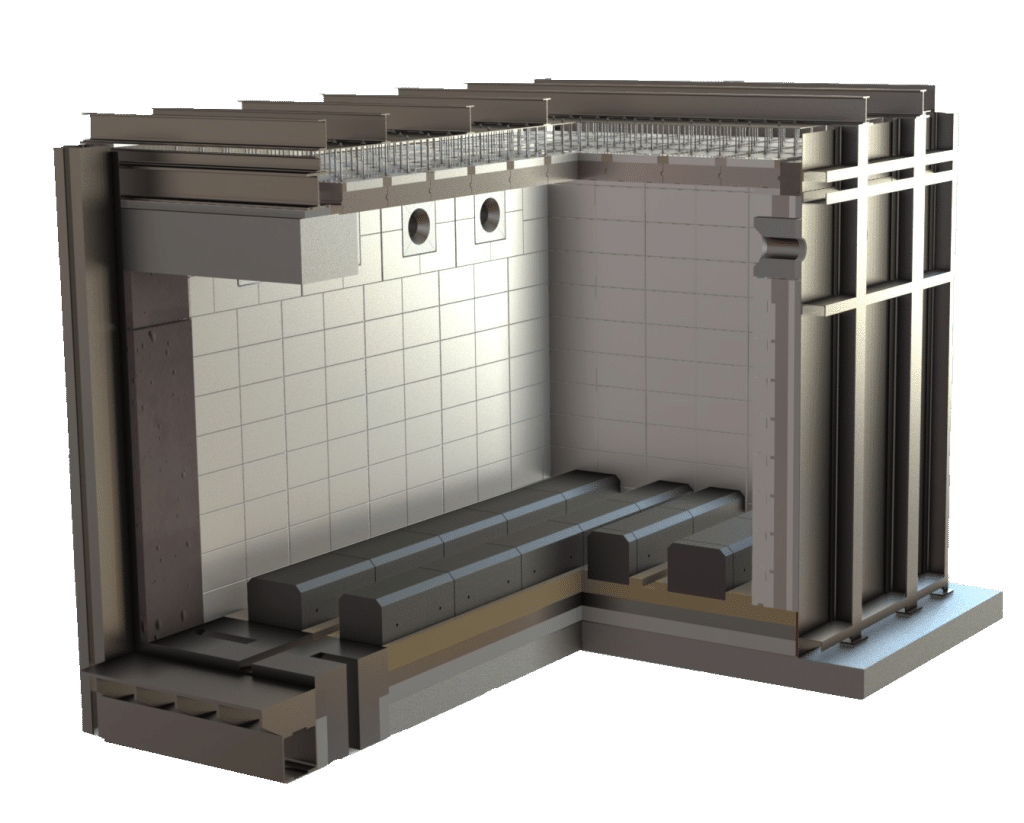

With the PUREBLOX 1400 TRB offers a breakthrough solution. These refractory insulating blocks, free from hazardous fibers and not classified as CMR, can withstand temperatures of up to 1,400°C. Their standard thickness of 310 mm provides thermal insulation comparable to existing fiber solutions, while offering superior mechanical strength.

This robustness prevents premature wall wear, prolongs equipment life and reduces the need for costly maintenance.

Health and performance without compromise

This new generation of refractory blocks guarantees stable, long-lasting performance in the most demanding environments. Thanks to their low porosity and linear thermal expansion, the PUREBLOX 1400 blocks ensure even, constant energy restitution.

The result: greater energy efficiency, reduced heat loss and optimized operating costs. For manufacturers, it's the assurance of reconciling productivity, safety and environmental performance.

The PUREBLOX 1400 solution was conceived and developed through the collaboration of our multidisciplinary teams, including our R&D team based in Nesles, our design office in Lyon, and our precast shapes experts at our production workshop in Neufchâtel-Hardelot. PUREBLOX 1400 is the result of unique expertise and a commitment to responsible innovation.

Tested under real-life industrial conditions, this technology offers a reliable and durable alternative to CMR-classified ceramic fibers. Easy to integrate into your installations, these insulating blocks represent a strong commitment to protecting operators, guaranteeing the durability of equipment, and helping industries move towards safer, environmentally-friendly solutions.