TRB is a Groupe CB company - Find More

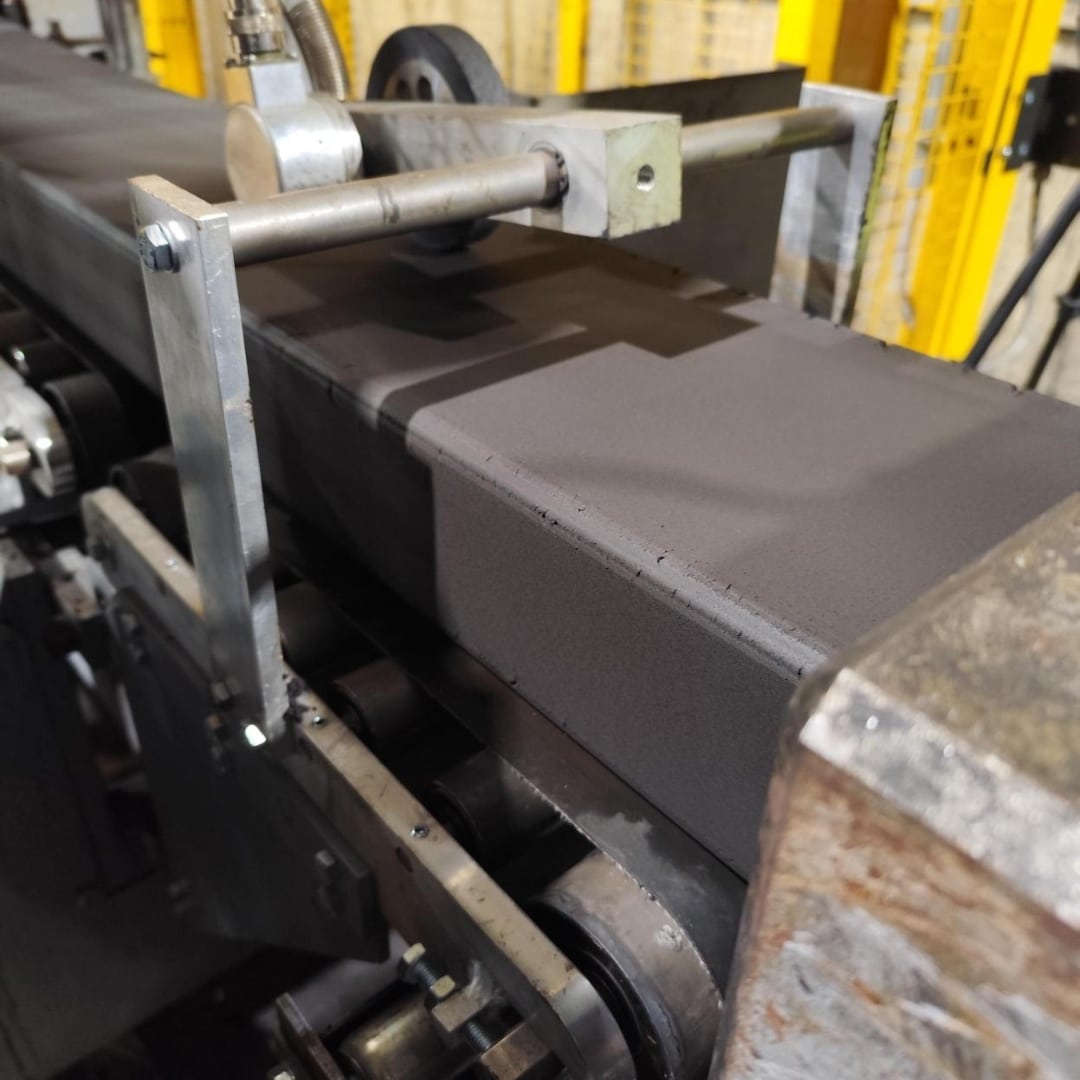

Tap Hole Clays

ECOTAP - The benchmark

in high-performance

Taphole Clay

Nearly 80 years

of expertise and

of innovation TRB

Every year, we produce 20,000 t of this organo-mineral material (ECOTAP), which is essential for casting molten metal. Our refractory aggregates are selected according to operating conditions, and include corundum, bauxite or quartz, among others. They are complemented by special additives such as Silicon Carbide or Carbonaceous materials to excel in all circumstances.

Every year, TRB produces 20,000 tonnes of ECOTAP organo-mineral Tapehole Clay, essential for sealing tapholes. Our formulations are based on a rigorous selection of refractory aggregates adapted to operating conditions(corundum, bauxite, quartz), enriched with specific additives such as silicon carbide or carbonaceous materials, to guarantee optimum performance in all configurations.

Thanks to this expertise, TRB now seals more than 40 blast furnaces in over 25 countries, with capacities ranging from 1,000 to 13,000 tonnes per day. Our solutions help extend the life of sensitive areas, stabilize production and reduce operating costs. A forerunner in innovation, TRB was also one of the first players to develop more environmentally-friendly Tapehole Clay formulations.

At a time when the market is evolving and European regulations are tightening, it's essential to anticipate these new requirements without compromising the quality of your products. To support you, we offer a range of unmarked solutions, combining compliance and optimum capping performance .

- From 1,000 t to 13,000 t/d

- 40 blast furnaces

- 25 countries worldwide

Customer satisfaction is based on a combination of several factors

The performance of our ECOTAP Tapehole Clay is based both on their technical design and on a demanding industrial organization. This combination guarantees reliable, long-lasting solutions adapted to the harshest environments.

By integrating cost control, continuous innovation and rigorous quality control, we provide our customers with products and services capable of meeting the requirements of modern production, while respecting environmental and economic standards.

The cornerstones of your success:

Taphole Clay, a key component of the blast furnace

Taphole Clay is essential for sealing the taphole, and plays a central role in the smooth operation of the blast furnace.

Its specific formulation requires perfect control of thermal and mechanical stresses.

Thanks to our proven expertise, our teams develop reliable, high-performance solutions tailored to the realities of the field.